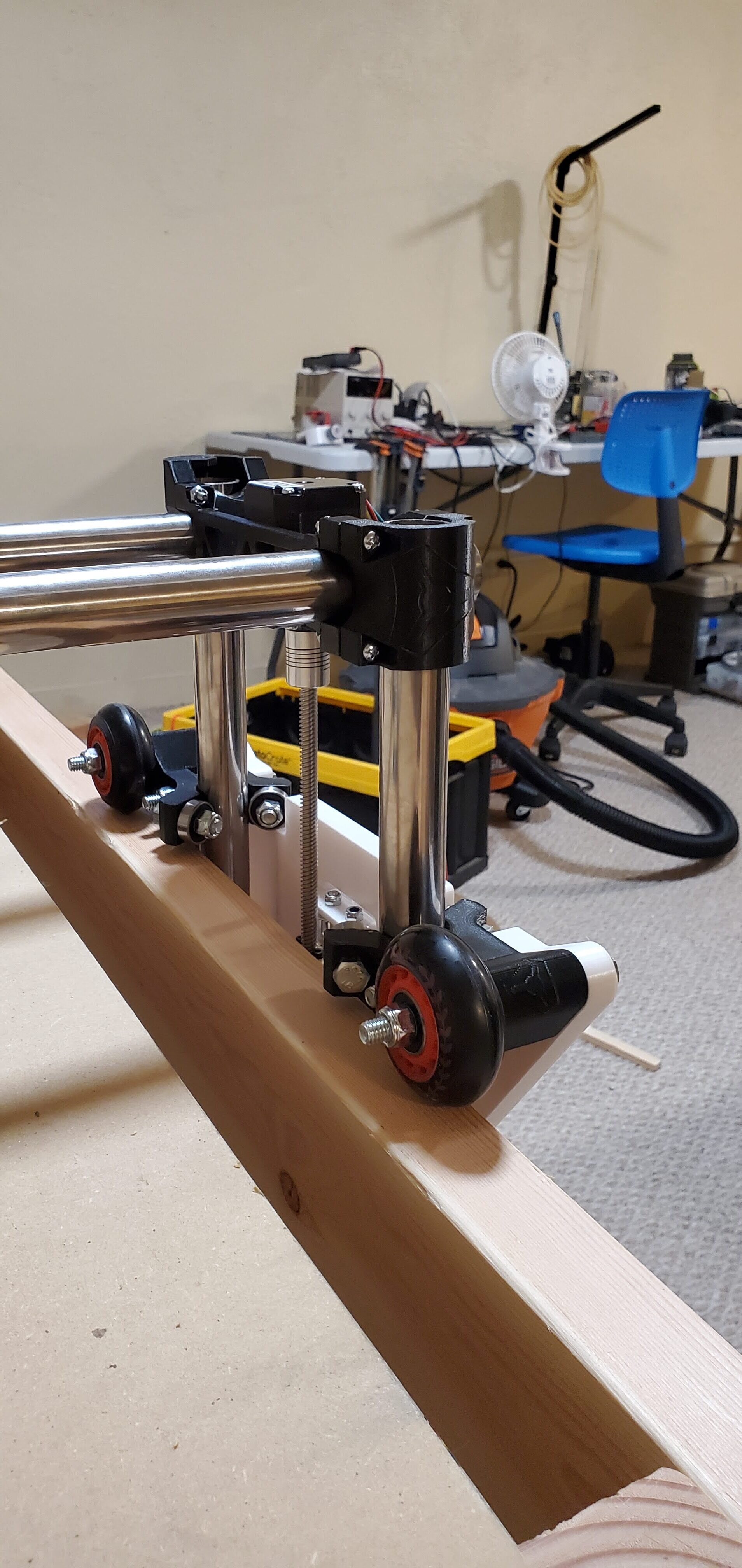

V1 Engineering LowRider 2 CNC

A 48”x96” iteration of an open-source cnc router platform

Make it stand out.

The V1 Engineering LowRider 2 is the only ultra low cost CNC routing platform capable of handling full sheet (48”x96”) materials. Link to V1 Engineering.

For under $800 (before lumber prices skyrocketed), it is quite the machine. Sure, its slow, it relies almost entirely on 3D printed structural components, and struggles to hold a 1mm tolerance over the entire work surface, but it is a true value proposition, and I do not regret building one of my own.

The whole project took a little over 3 weeks of long nights and early mornings to finally have a usable machine. Determining an appropriate and efficient workflow was an entirely separate problem.

All components where printed on my personal Prusa i3 Mk3s in PLA and PETG, depending on stresses involved. 65 hours total print time and over 1.8kg of plastic used.

General Information:

Working area: 50”x98”

700W Spindle (Ridgid 2401)

Maximum movement speed: 300 mm/s

Average cutting speed for laminate plywood (OSB) at 1/4” DOC: 15mm/s

Needed to add some rigidity to the roller plate system, and opted to have a local garage hobbyist plasma cut steel Y-Gantry plates. Have yet to test out increased rigidity as of 7/18/2021, however preliminary messing around shows moderate improvement over printed plastic multipiece gantry pieces.

Acrylic sign cut test

Here is a demonstration of the CNC during the cutting of the Golden Fly Shop Faux Neon Sign.